Categories

The welding industry is among the most diverse in terms of materials, machinery, types of work and exposure intensity. Italy, for its part, ranks among the top positions as a number of personnel potentially engaged in welding tasks, given the large number of companies manufacturing metal products or mechanical equipment.

It becomes, therefore, very important, to evaluate all the aspects involved in the choice of machinery technology, since it has repercussions on the type and quantity of pollutants that come out.

As for the various parameters, it is good to know that they affect the amount of fumes produced, as demonstrated in arc welding, where the higher the current intensity, the greater the pollutants produced.

How to reduce pollutants with installations and suction systems

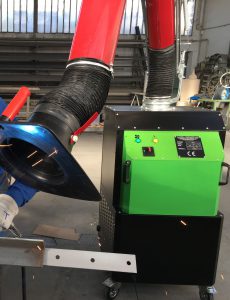

Regardless of the machinery and the technology used, the suction systems are the most concrete and suitable solution for safeguarding health in industrial work.

| Suction arm, single or centrally installed | Suction bench with suction table and retaining walls or suction arm | Portable purifier with HEPA 99.95% filtration and activated carbon | ||

|

|

|

||

| ADVANTAGES – Allows work at undefined workstation – Collection near the source – Reduced flow rate |

ADVANTAGES – Extraction without welding intervention – The work plan facilitates operations |

ADVANTAGES – Allows several welding points to be reached – Collection near the source – Reduced flow rate |