Categories

Increasingly complex and articulated suction systems, increased air filtration levels to protect the environment as well as increasing the internal suction standards to companies have led to an increasing demand for pressure in the sizing of a centrifugal fan, resulting in increased rotation speed also known as RPM.

More RPM equal acoustic impact increased

This increase in pressure and engine revolutions often results in an inevitable increase in the noise of fans that can not always be installed in isolated areas and in any case must comply with precise acoustic regulations that normally place as a maximum limit the 75 sb(A) for industrial areas and internal production layouts.

With this article we do not want to go into the merits of regulations and limits but instead examine the evolution of the soundproof fan box.

Box fan and suction systems: a 20 years long development

It was the early 90’s when the soundproofing kits for centrifugal fans for civil use were timidly born, while the aphonic covers were already more used for large fans in production contexts, without yet covering the medium-low power band, interested in this type of applications only in recent years as a result of increased sensitivity to environmental noise.

Thanks to this development the soundproofing box also known as “box” has now become almost compulsory in an industrial intake system that respects, also to avoid then facing the problem passively with activities of noise treatment.

Construction and features

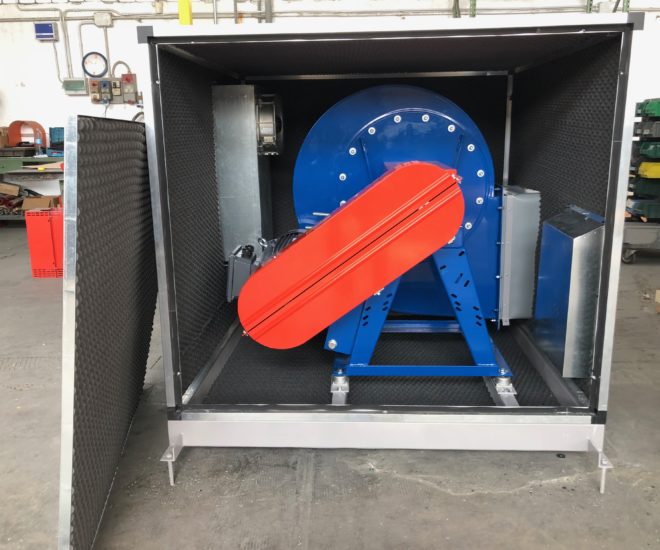

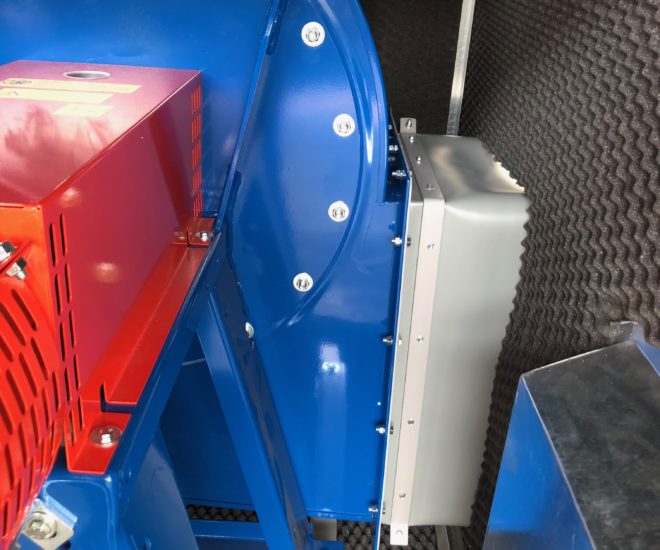

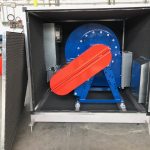

But let’s get to the point and see how a box complies with the highest national and international standards, as well as industry 4.0 certified systems.

|  |

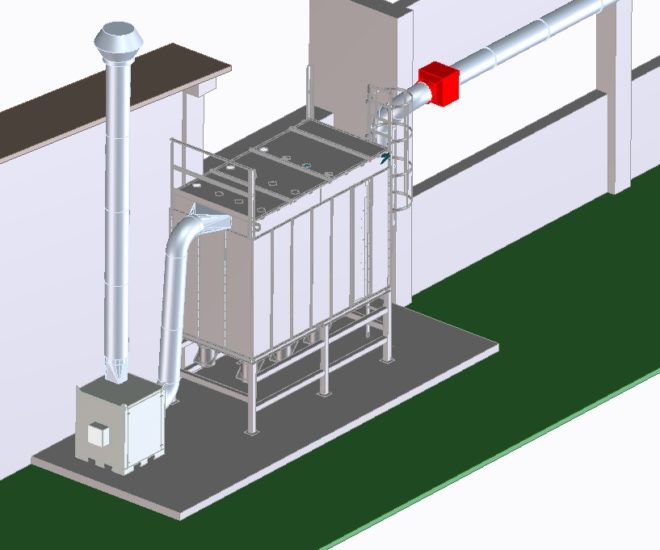

This configuration has standard sizes ranging from 900x900x1100H up to 2500x2100x2100.

Noise abatement and noise analysis for box fans.

Thanks to the use of the box we are often able to reduce the noise of the suction systems even of 15db(A) compared to normal values, provided that silencers on suction and discharge are used.

But since each machine has different directivity, this level is to be considered as average and not the maximum point value (for this value it is to be cautiously increased by 3 dB(A) the average value calculated).

The sound pressure level of the installed machine depends, in addition to its sound emission, also on the following contributions:

- Ambient background noise (significant if not less than 10 dB(A) from the calculated sound pressure level)

- Reverberation of the environment, depending on its size and the sound absorption of its surfaces

- Positioning close to another sound source (it is important to remember that doubling or halving the sound power you get a difference of 3db)

- Positioning of the source near reflective surfaces: the values shown in the catalog take into account the only floor positioning (1/2 spherical propagation)

For other placements take into account the following corrective factors:

- Positioning next to a reflective wall (1 4 spherical propagation) + 3 dB(A)

- Positioning in corner next to two reflective walls (1/8 spherical propagation) + 6 dB(A)

For other placements take into account the following corrective factors:

- Positioning next to a reflective wall (1 4 spherical propagation) + 3 dB(A)

- Positioning in corner next to two reflective walls (1/8 spherical propagation) + 6 dB(A)

It is therefore important to remember that the noise values usually indicated in the catalogues are recorded according to regulations that prescribe well-defined environmental and installation conditions for the industrial suction systems.

Thank you for your attention!

Gamma Impianti Technical office

Books or sources