Categories

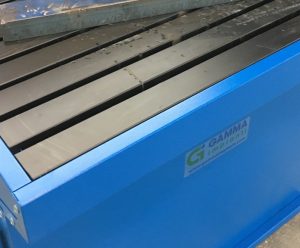

The suction bench, an operation and technical analysis

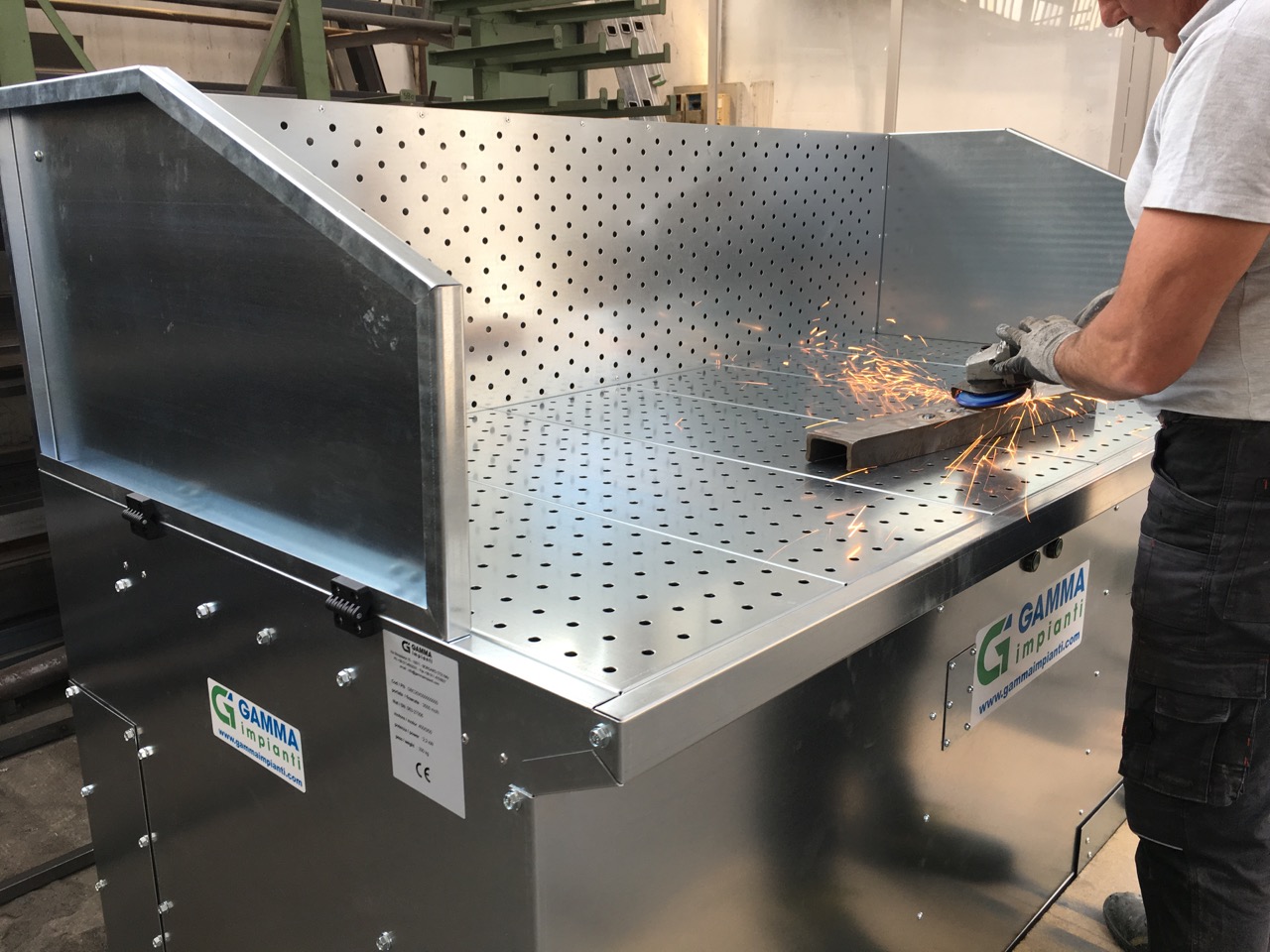

Gamma Impianti suction bench is an excellent prevention solution both because it provides a comfortable and useful work surface for the operator, and because it represents a valid solution for the protection of operators from the fumes and dust produced during the processing of:

- Sanding metals or composite materials

- Metal grinding and surface treatments

- Metal, composite or plastic welding

- Deburring and metal scraping

- Portable plasma cutting

Definitely interesting this video that shows the smoke difference when the suction bench is turned off or on during the welding phase

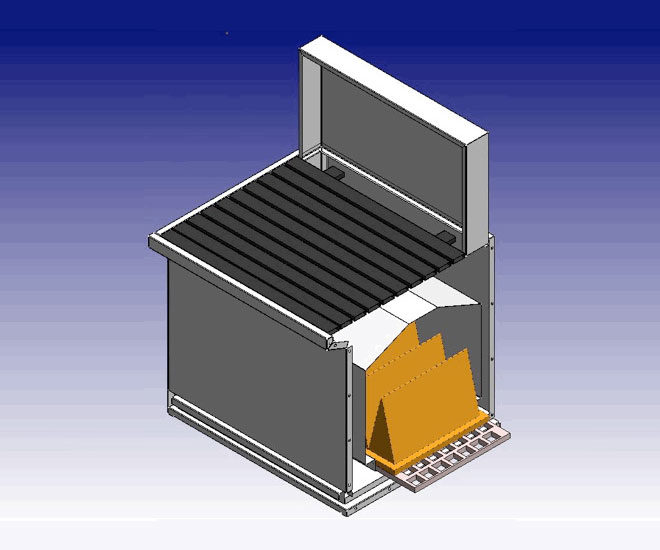

| The suction bench is normally equipped with a support surface composed of tubular steel slats, cut to size and mounted in order to unify the capacity and suction capacity on the work surface. The slats are dimensioned to have a high weight capacity and are easily removable to carry out maintenance or in case a foreign body accidentally falls. The smoke and dust are sucked through the work surface which is held in depression by the air flow to the inside of the bench. |  |

| The heaviest dust thanks to the design of the internal flows are deposited in the collection drawer and the lighter ones in the filtration system. The collection drawer can be easily removed by hand and emptied or sucked with an industrial extractor.

|  |

| Depending on the version, the suction bench is equipped with different side and rear walls, or in some cases it can also be without. The bench walls can be drilled and sucked in the case of sanding or equipped with a metal mesh to stop the particles at high speed of grinding metals. |  |

| For example, the suction bench for cartridges sanding and filtration is equipped with a microperforated surface and wall, specifically designed to collect dust and limit as much as possible the contact with the respiratory tract of the operator. |  |

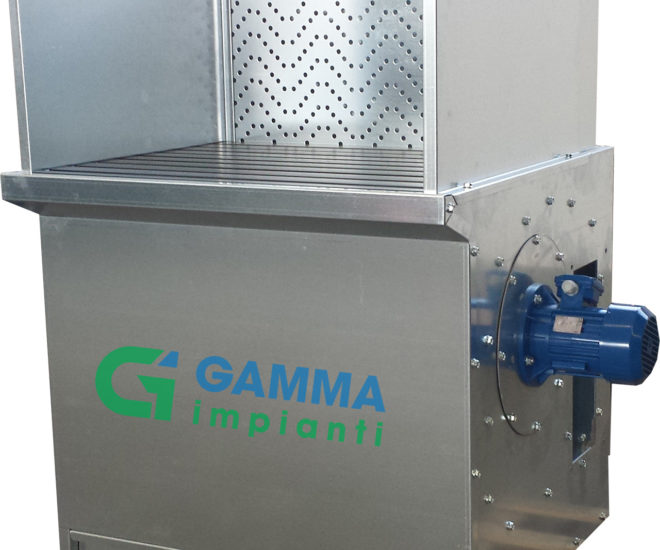

| Extractors and filtration systems can be inserted into the structure or alternatively placed outside and connected through a pipeline. In the case of the suction bench with integrated filters, they can be easily removed for changing by a side door. |  |

| On one of the two sides the air expulsion hole is provided, to which can be connected the expulsion pipe outside or a silenced channel for return to the environment where allowed by the regulations. If it is to be connected to a centralized suction system, it is produced in a simple version, without engine and filters. |  |

Available versions

GBA – suction bench with collection drawer but without filters, to be connected to a suction system equipped with a fan

GBF – suction bench with collection drawer and pocket filters, to be connected to a suction system for expulsion outside and equipped with fan

GCA – suction bench with collection drawer, cartridge filters, automatic cleaning with compressed air and fan, to be connected to a suction system for external ejection, or on request supplied with short silencer for the return to the filtered air in the environment

Contact us for technical advice or for a quotation of the right suction bench

Do you need something different from the suction bench? Check our product range for industrial suction or our systems.

Bibliography

Wikipedia: air suction systems