During maintenance and manufacturing processes in the railway industry, micro-dust, chips and substances are released which are harmful to the health of operators.

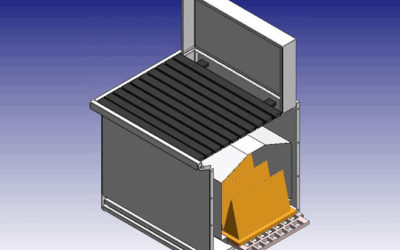

Gamma impianti solves these problems by realising extraction systems, extraction hoods, booths and stationary and mobile extraction and filtering equipment designed to meet the needs of this kind of production.

The goal is to capture pollutants, conveye them to dust or activated carbon filters for the removal of SOV and VOC. Our systems captures:

- dust from under body-processing of the vehicle

- dust from sanding/cutting/finishing composite materials

- dust from construction work of coaches

- SOV filtration with activated carbon filters by painting operations, manual/vacuum stratifying

- fumes and dust from welding, carpentry and metal finishing

- dust and chips from woodworking operations

- epoxy resins from kilns/stabilization

- fumes from die-cast aluminium and its alloys

- oil/aerosol mists from machining

- liquid painting

Most of these processes are performed in hazardous environments with risk of explosion, therefore we employ ATEX certified materials and technologies.

We offer extraction systems, extraction hoods, booths or stationary and mobile extraction and filtering equipment designed to meet the needs of railway industry production.