Industrial shed ventilation for heat dissipation and air exchange

Industrial shed ventilation for heat dissipation and air exchange

Customer request

Reduce inner temperature of an industrial shed, to prevent overheating of machinery both during day and night shifts, when for safety reasons all windows must stay closed.

Design

After a careful analysis of thermal loads generated by machinery and environment, our Technical Department opted for the forced ventilation of the industrial shed. Ideal solution to cool down industrial buildings with no air conditioning system during summer.

Normally, in this kind of plant, three to fifteen air exchanges per hour can be foreseen depending on the machine features. The extracted air is then reintegrated in the environment by openings, grids or fans.

Air extraction

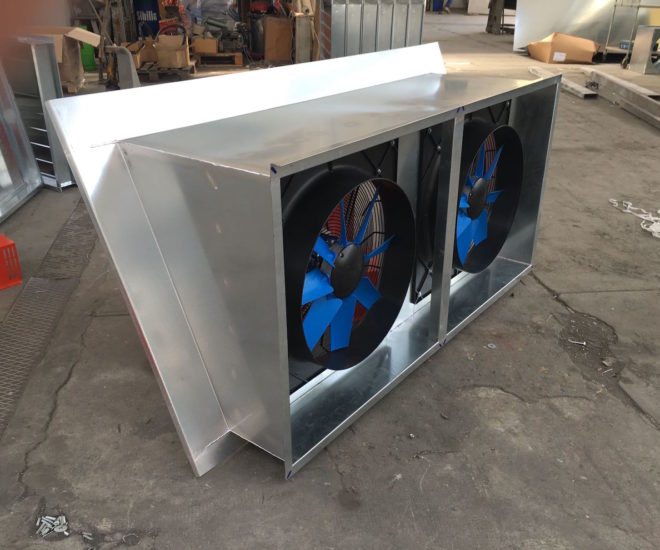

In this case, our designers opted for 10 exchanges/hour, for a consequent overall plant capacity equal to approximately 63,000 m3/h. All this has been obtained by the installation of four 2VE560-SH ventilation groups, specifically designed for installation in industrial sheds with SHED roofs or skylights.

Replenishing

External air is inlet in the room by effect of the vacuum generated by the fans, creating a horizontal current close to the ceiling capable to eject hot air, which naturally goes upwards. Inlet grids has been positioned along the wall opposite to the fans and coupled to motorized dampers, which automatically close when the fans are off.

Control of the plant through an on/off control each four extractors, in order to split in half capacity.

In conclusion, night operator can operate with ventilation turning on the fans and closing all windows, so as to ventilate the room mechanically.

Associate systems

Extraction on the machine

Temperature and humidity control

Related products

Ask a quotation or contact us

Those who have already chosen us...