Bag filters for fumes and dust

Bag filters are designed by Gamma impanti for dry filtration of shrinkage, fumes, dust, powder and drosses of different sizes produced by industrial and manufacturing works, such as: woodworking, foundry, grinding, welding and puncturing, thermal breaking, metal cleaning, sandblasting, metal sprying, polishing, tool sharpening, turning and dry milling.

Bag filters types

- standard: in galvanized plate;

- on-demand: in stainless or varnished steel.

Extras on-demand

- Filtering bags for specific powders;

- Electrical panel to check aspirator and after-cleaning conditions;

- Panel with Inverter for evergy saving and performance control;

- Bins with balanced flow bags;

- Safety rail and ladder;

- ATEX zone 22 3D components;

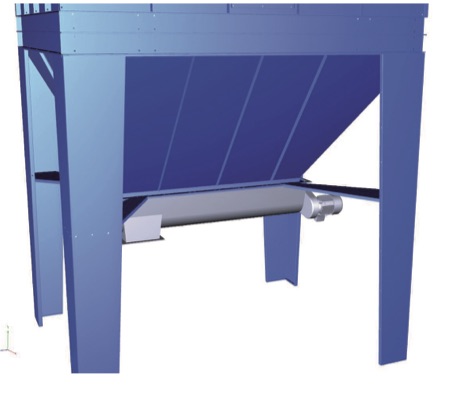

- Cochlea and rotovalve for powder discharge;

- Fire detection and suppression system.

Bag filters in detais

Our bag filters are designed with a 3D software. They consist in self-supporting panels of top quality steel plate, worked with numerically controlled punching machines and folded by a 6-axis robot bender. Each panel is fringed with silicone sealant and they are bolted together with high-tensile bolts.

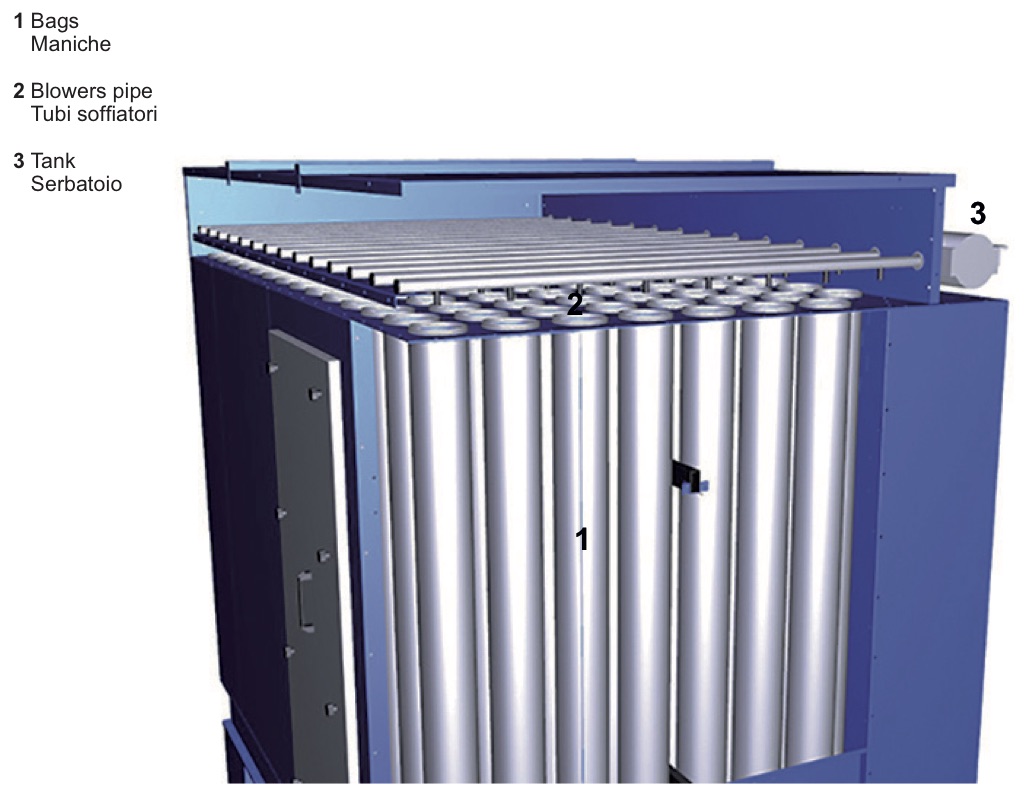

The machine’s main body contains the real filtering core of the machine, separated in two sections: the upper suction system with automized air-compressed cleaning system and the central part where bags and baskets are.

Within bag filters, venturi cones are mounted on baskets with idraulic seals, with the specific aim to improve efficiency of the auto-cleaning body.

Polluted air flow enters spaces between venturi cones and passes through filtering bags catching powders. Then, filtered air proceeds in the upper body towards the aspirator. Lastly, it is discharged outside.

Regulatory and on-line reference

https://it.wikipedia.org/wiki/Filtro_a_maniche

D.Lgs. 81/2008 (da Art. 221 a 243) Title IX harmful substances

sectors of application

Metalwork Varnishing Aerospace Railway Graphical and printing industry Pharmaceutical field Marine industry Food IndustryAssociate systems

4.0 extraction systems

Welding fumes extraction

Aspiration for grinding

Extraction on the machine

Extraction for varnishing

Chip extraction

Noise treatment

Clean rooms

Temperature and humidity control

Air conditioning and heating

Ask a quotation or contact us

Those who have already chosen us...