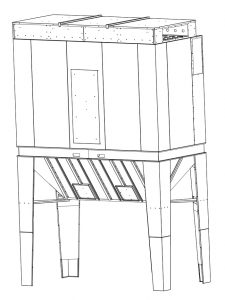

GFM bag filters for fumes and dust

GFM bag filtering groups are designed for dry abatement of fumes, dust and drosses with fine and medium grain size, which could derive from varied industrial workings.

These technology is recommended for heavy-duty units, in fields as woodworking, mechanichal industry, mineral processing, metalworking, waste sector and ceramic, paper, plastic, iron and steel industry.

These filters grant air quality within production environments and protect who works there.

Main features

- Suction surface 30 to 900 mq according to flow rate and pollutings to treat;

- Self-cleaning system with compressed air with settable timer;

- Powder exhausting through collector bin or automated rotovalve;

- Air coming in and out from different sides.

Structure

- Standard: galvanized steel sheet;

- On-demand: inox or varnished steel.

Extras

- Filter media for specific powders;

- Electric panel to control extraction and cleaning;

- Panel with inverter for energy saving and performance check;

- Bin with balanced-flow bags;

- Safety rail and ladder;

- ATEX zone 22 3D components;

- Exhaust powders cochlea and rotovalve;

- Fire detection and suppression system.

| GFM filters in detail Bag filters consist in self-supporting panels of top quality steel plate, worked with numerically controlled punching machines and folded by a 6-axis robot bender. Each panel is fringed with silicone sealant and bolted together among them with high-tensile bolts. |

| Filtering bags are cylinders with bottom on one edge and SNAP RING mounting system on the other, to quickly mount and dismount them from the bag bench and to grant sealing against dust. Normally, filtering bags are made of 500 gr/m2 aramid fabric, waterproof and anti-acid basic treated. They are specially recommended for abrasive powder with medium grain size, in dry environment, up to 180°C. In particular, bags raise filtration threshold providing easy detachment of dust, which normally sticks to the filtering surface. Aramid fabric improves filtration efficiency and loss less load compared to traditional fabric as cotton. Fabric can be replaced according to the kind and quantity of powders to be treated. Within the bags, there are galvanized steel baskets to keep the bag open (it works in depression). Baskets are equipped with customized venturi cones mounted with a sealing gasket. Their aim is to improve efficiency of the shot of air for automated cleaning. Polluted air flow enters spaces between venturi cones and passes through filtering bags catching powders. Then, filtered air proceeds in the upper body towards the aspirator. Lastly, it is discharged outside. |

sectors of application

Machinery and production lines Metalwork Aerospace Railway Pharmaceutical field Marine industry Food IndustryRelated products

Ask a quotation or contact us

Associate systems

Those who have already chosen us...