Double arm trailer-mounted purifier for welding fumes

Trailer-mounted purifier for welding fumes MFU16W23 can be easily moved where it’s needed thanks to its compact size, wheels and convenient handlings. Once there, it aspires fumes through its self-supporting suction arm ending in a hood with handling, to extract emissions straight from the source.

This model is equipped with a double suction arm with the aim to locate the machine between two working stations, so to extract from both sides at the same time.

ADVANTAGES

- Double suction arm for maximum level of flexibility.

- Safety granted: led alarm on the panel warns when filters need maintenance.

- Quick: fumes suction straight from the source thanks to a high flow rate.

- Mobile: it can reach any working station.

- Filtration: with absolute filter H13 ≥99.95%.

- 1500W single-phase power easy connectable via Shuko socket.

- Easy maintenance: primary filter has 500 hours of life.

| How the purifier works Pollutants are aspired from the flexible suction arms. Then, pollutants are filtered to 99,95% of efficiency while crossing the purifier towards the bottom. Finally, odours are absorbed by active carbons. Environment safety Level of clogging is constantly monitored by a system with a led signal, which advise when it is necessary to clean or substitute filters. |  |

Technical data

Rated capacity 1.500 mc/h

Engine power 1,5kW 220/1/50

Total weight 110 kg ca

Filtration:

Stage 1 – sparkproof metallic filter G3

Stage 2 – acrylic filter G4 (following EN 779:2012)

Stage 3 – absolute filter H13 ≥99.95% (@ MPPS following EN 1822:2009)

Stage 4 – active carbons filter for odours

Structure

Supporting structure of strong galvanised or powder-coated iron, with practical handles and 4 pivoting wheels with brake.

Electrical panel in accordance with CE rules, with on/off switch for ventilation and warning led for filter clogging.

Centrifugal fan with simple inlet, directly paired to asynchronous single-phase engine.

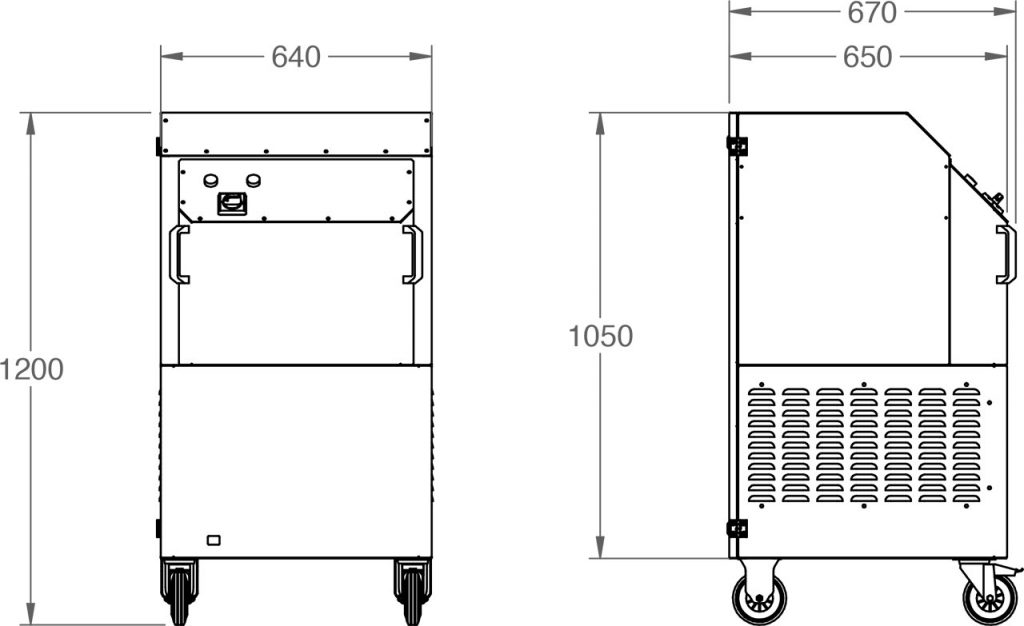

Size

sectors of application

Machinery and production lines Metalwork Aerospace Railway Marine industry Workshops and overhaul centresAsk a quotation or contact us

Associate systems

Those who have already chosen us...