Categories

The metal grinder is the operator who smooths metal surfaces using abrasive tools (grinding wheels or grinders). The result of this process is the removal of material, or small chips, to obtain surfaces of high finish.

Since the production of chips and airborne pollutants occurs during grinding, there are some risk factors to take into account that are:

- Musculoskeletal injuries caused by repetitive work

- Respiratory or dermatological diseases due to dust contact or inhalation

- Trauma due to handling of parts, falls, slips and vibrations

- Fire risk

To guarantee the worker a healthy environment, it is necessary to equip oneself with suction benches for grinding, the ideal solution for the localized aspiration of fumes and dusts.

Grinding suction benches: the best solution for dust extraction

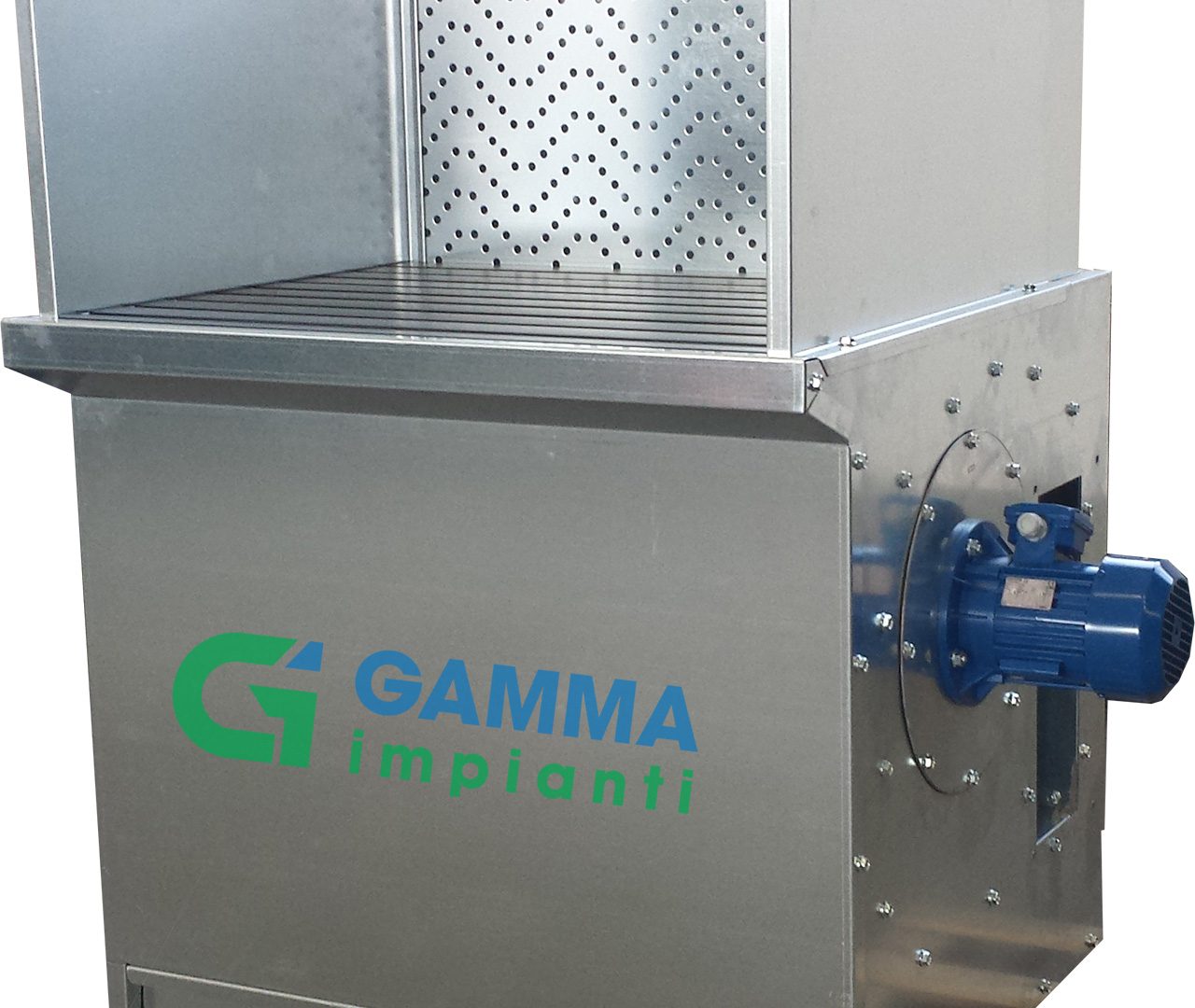

The suction grinding benches, ergonomically designed and made in various sizes, make safe the operations of grinding, frosting, polishing, cleaning of small parts, which are placed on the workbench.

The suction benches for grinding are the ideal technical solution for all companies that in their production cycle perform surface treatments by hand or with tools, or where parts washing, degreasing and small touches are carried out.

Main applications:

– Metal welding, sanding, grinding, polishing and smoothing

– Mechanical engineering, wood and marble

– Suction of solvents and vapours during washing operations

Operation

The suction floor with loopholes is kept in a depression in order to capture the pollutants, the heavier poor end up in the collection drawer and the lighter ones in the filtration system that can be on board of the bench or centralized.

Extractors and filtration systems can be inserted into the bench structure or alternatively placed outside and connected through a pipeline.

Gamma Impianti offers different types of standard benches or tailor-made to measure to customer specifications, in fully galvanized or painted version.