Categories

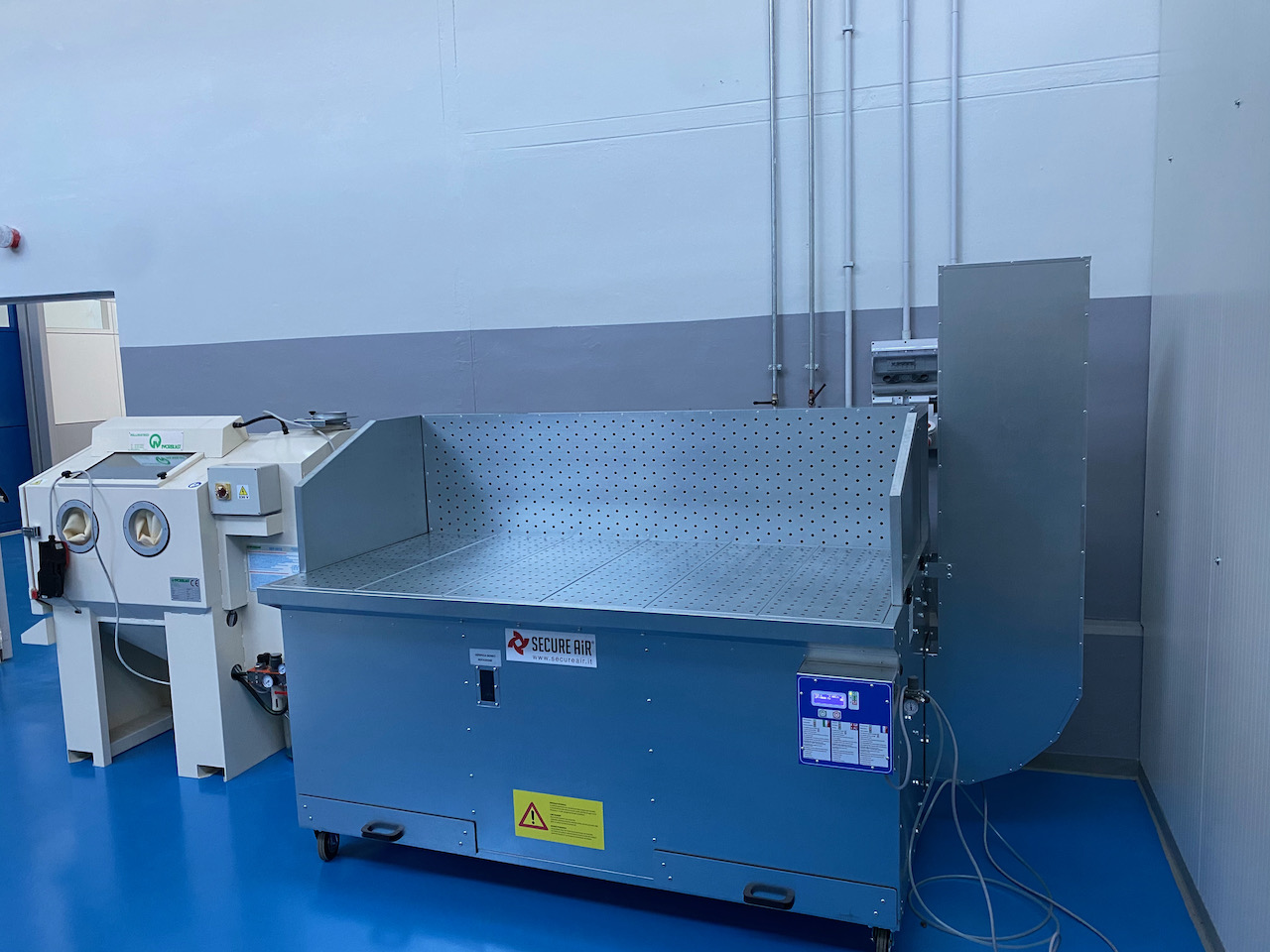

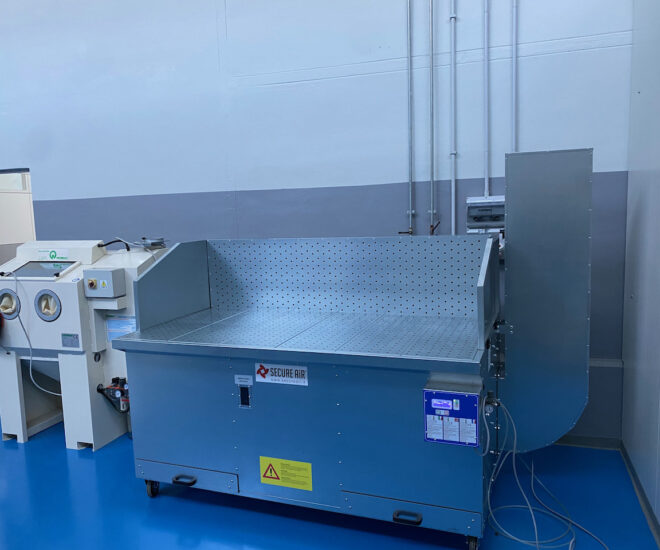

We are proud to have supported this important Turin reality with our latest generation suction bench that, during the prototyping operations in the additive laboratory, had the problem of aerodisperse powders, generated during the grinding and deburring operations of the pieces, then blown using compressed air.

Fumes and micro powders were absolutely to be contained and aspirated in order to protect the respiratory tract and surrounding electronic equipment.

After a specific technical comparison between technical offices we decided to solve the problem by using the ready-to-use suction bench of our GBC series which, thanks to its suction and filtration characteristics with 99% efficiency, represents an important innovation in professional suction and filtration systems.

What is CIM 4.0?

Thanks to its industrial partners (23 major companies mainly large) and two large research centers for technical-scientific skills (Polytechnic and University of Turin) CIM 4.0 is the reference point for everything related to technology transfer, the dissemination of skills and specializations related to technologically advanced production cycles and the training and culture 4.0 of companies. The task of the organization, through the activation of “pilot lines” or manufacturing demonstration lines, is to support the technological maturation of innovative processes and products, By giving companies a structure that can simplify and make more competitive the approach to new markets.

Enabling Technologies linked to the Pilot Lines are:

1. Metal additive manufacturing (AM) and laser production

2. Smart grids, smart meters, and energy efficiency

3. IoT industrial, HW-SW platforms, sensors, cloud and connectivity

4. Artificial intelligence, data analytics, and cyber security

The independent suction bench solution for 3D printing

Increasingly used during these innovative production techniques, the suction bench allows you to work safely without disrupting industrial and craft processes, thanks to its exclusive features:

- High suction capacity of fumes and micro airborne dust dispersed both from the top and from the front wall

- High capacity extractor integrated in the body bench

- Antistatic polyester cartridge filtration with final efficiency 99.9%

- Compressed air cartridge cleaning system for maximum filtration efficiency maintained over time

- Control and control unit of the extraction bench system, with display and maintenance warnings

- Wheels for easy handling of the suction bench that becomes an independent station without exhaust chimneys outside

- Vertical silencer for exhaust in filtered air environment

Thanks to this compact and flexible solution, the CIM 4.0 additive laboratory is safe from fumes and dust.