Categories

Welding suction benches are a good solution to protect the operator from all those pollutants that are produced during the welding of metals.

It is well known that the welding of metals, depending on the technique used, generates fumes, dust and gases containing dozens of different and harmful chemicals, produced from the same processed material that remainssuspended in the air in the form of metal particles or metal derivatives (for example oxides), fillers (electrodes, rod electrodes, lead, welding powder, etc.) or these are removed from the covering as paints, coatings, and detergents.

Breathing welding fumes can cause operators health problems.

For example, the fumes produced during the welding of stainless steels contain metals with high toxicity such as chromium and nickel, and in the case of MIG welding of light alloys, exposure to aluminium manganese and lead may occur, often present in particular filler materials.

For each process the right suction system

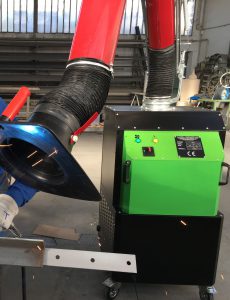

| Suction arm, single or installed in a centrally system | Suction bench with suction table and retaining walls or suction arm | Portable purifier with HEPA 99.95% filtration and activated carbon | ||

|  |  | ||

| ADVANTAGES – Allows work at undefined workstation – Collection near the source – Reduced flow rate | ADVANTAGES – Extraction without welding – The work plan facilitates operations | ADVANTAGES – Allows several welding points to be reached – Collection near the source – Reduced flow rate |

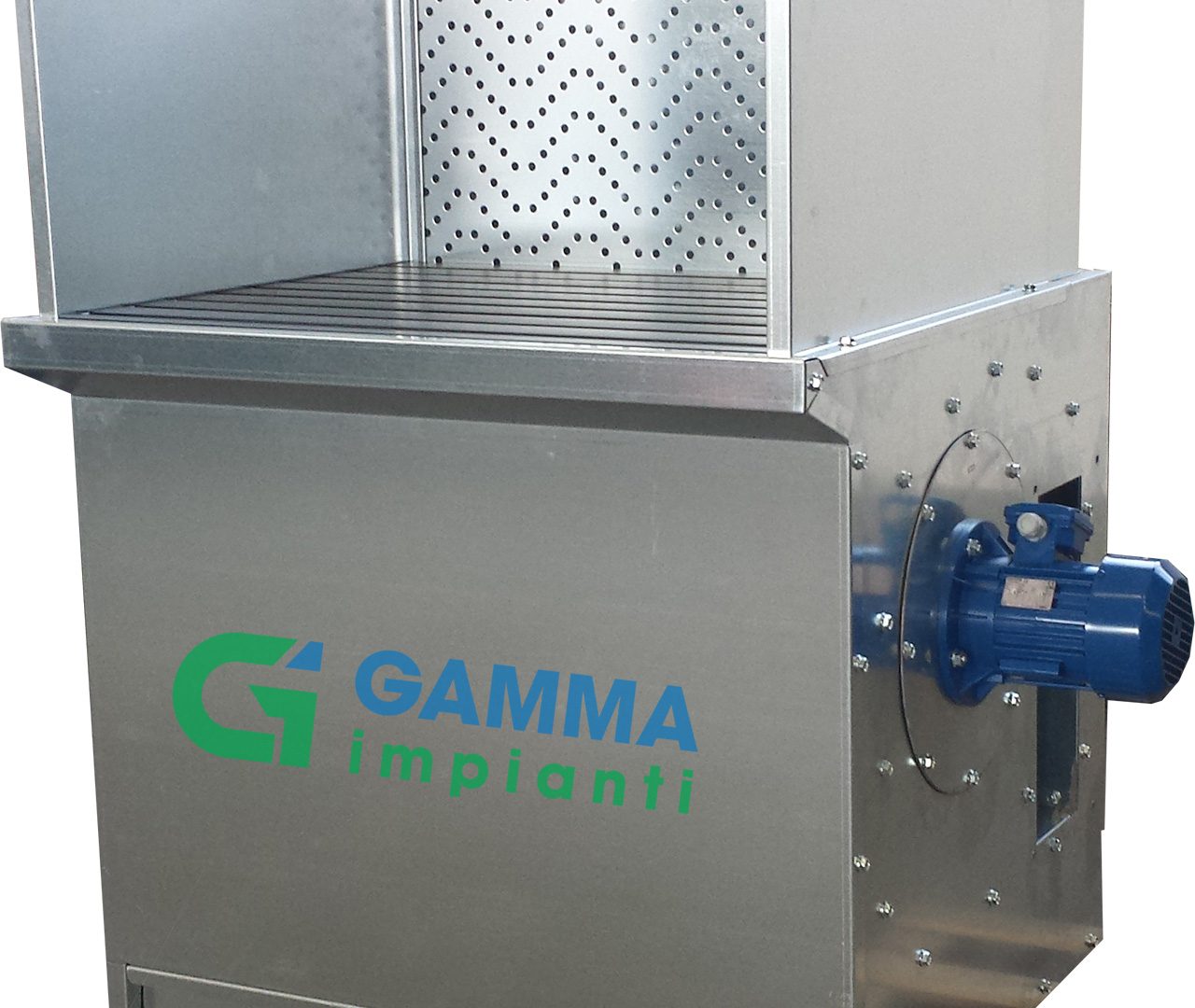

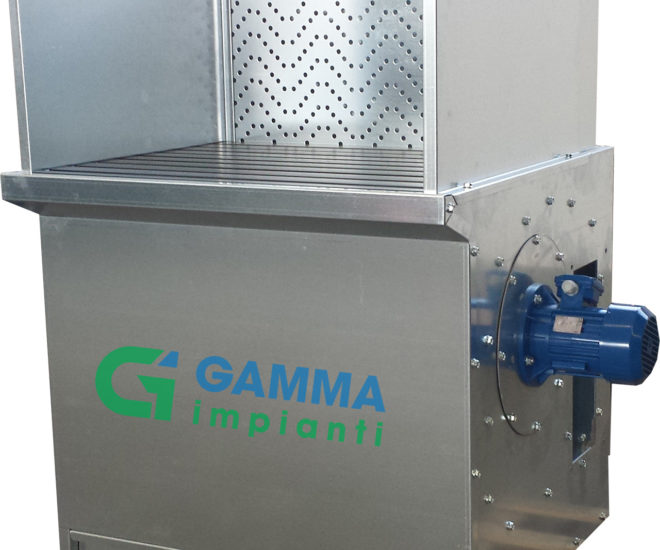

The welding suction benchesare work tables equipped with a suction plate and, depending on their use, they can be equipped with a rear suction wall and an articulated arm to connect a localized suction and directed to a precise area of the bench, where welding fumes are generated.