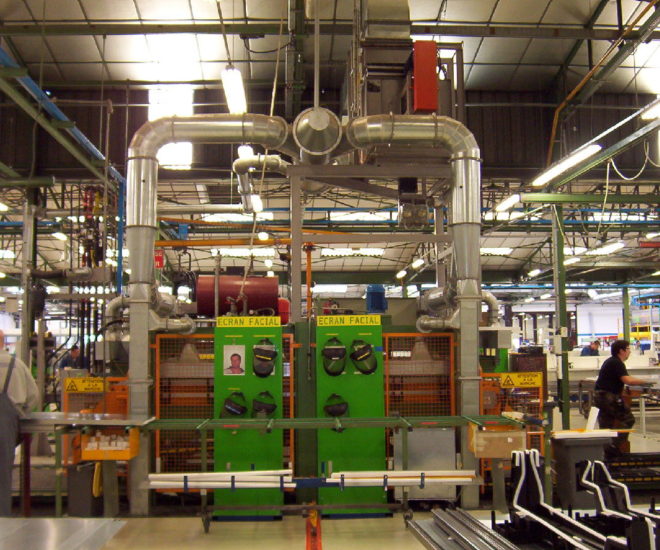

Polyurethane injection fumes extraction

Customer request

Design and implementation of the extraction plant for a line producing refrigerator cabinets in Russia.

During the foaming operation potentially explosive gas extractions are released.

The refrigerator cabinets are produced in cabin lines of about 10-12 units.

Design and manufacture

Pinpoint extraction on the equipment with extraction hoods connected to a series of suction manifolds, to centrifugal fans and to ejection chimneys outside the building.

Taking in consideration the dangerousness of the polluting elements and to ensure extraction even in case of technical failure, we installed two fans on each line, one as backup. They can also operate simultaneously to have an extra air capacity.

Rated capacity of each line 20,000 m3/h.

The design involved the sizing of the exact speeds of air flow in extraction and discharge ducts, with consequent calculation of the overall load losses depending on the path of the tubes and of the other components, all custom designed.

Special Notes

In this case, engineering phase had to consider that all components were to be sent for subsequent installation in the production site abroad. For this reason, our Technical Department designes each component and provides an overall numbered drawing so that everything can be easily assembled on site.

sectors of application

Machinery and production linesAssociate systems

Ask a quotation or contact us

Those who have already chosen us...